To pick the right engine hoist capacity the first time, start by accurately determining your engine’s weight and size using manufacturer specs or scales. Choose a hoist with at least 10-20% higher capacity than the engine’s weight to guarantee safety and account for hardware and shifting. Always inspect the hoist, secure the load properly, lift slowly, and stay within load limits. Following these steps helps prevent accidents, and if you keep exploring, you’ll learn how to do it safely and effectively.

Key Takeaways

- Always determine your engine’s weight and size accurately before selecting a hoist.

- Choose a hoist with a capacity 10-20% higher than the engine’s weight for safety.

- Consider the type of hoist (hydraulic, portable, shop crane) suited to your lifting needs.

- Regularly inspect and maintain the hoist to ensure safe operation and prevent overload.

- Secure the load properly, lift slowly, and keep the area clear to ensure safe lifting practices.

Why Choosing the Right Engine Hoist Capacity Matters

Choosing the right engine hoist capacity is essential because using a hoist that can’t handle your engine’s weight can lead to safety hazards or equipment failure. If the hoist isn’t compatible with your engine’s size and weight, you risk dropping the engine or damaging the hoist. Proper engine compatibility guarantees the hoist can lift safely and efficiently, reducing the chance of accidents. Lifting safety depends on selecting a capacity that exceeds your engine’s weight, providing a margin of error. Overloading a hoist can cause equipment failure and serious injury. Always verify your engine’s weight and size before choosing a hoist. Ensuring the correct capacity not only protects you but also maintains the longevity of your lifting equipment. Additionally, understanding the contrast ratio of your equipment can help you select a hoist that performs reliably in various environments. Being aware of safety standards ensures your lifting setup meets necessary regulations and best practices, further enhancing safety and performance.

How to Determine Your Engine’s Weight and Size

Wondering how to accurately determine your engine’s weight and size? Start by checking the manufacturer’s specifications, which often list engine weight and dimensions. If those aren’t available, use a scale to weigh the engine if it’s out of the vehicle, or consult repair manuals and online resources for typical engine weight and dimensions for your engine’s make and model. Measure engine dimensions—length, width, and height—with a tape measure, ensuring you account for any protruding parts. Keep in mind that engine weight can vary due to accessories or modifications. Understanding engine weight variability helps in selecting the right hoist capacity and ensures safety. Additionally, considering accurate measurements can prevent overestimating or underestimating the required capacity. Recognizing weight fluctuations in your engine can further refine your choice of hoist, enhancing safety and efficiency. Being aware of weight differences based on modifications can improve your planning process. Knowing your engine’s weight and size precisely can also help you avoid potential overloading hazards during lifting. Precisely knowing your engine’s weight and size ensures you select an appropriate hoist capacity, preventing safety hazards and equipment damage. Taking these steps provides a solid foundation for choosing the right engine hoist.

What Types of Engine Hoists Are Available and Their Capacities

There are several common types of engine hoists, each designed for specific tasks and weight capacities. You’ll find models with capacities ranging from a few hundred pounds to over a ton, so choosing the right one hinges on your engine’s size. Knowing how to select the appropriate hoist type and capacity guarantees safe and efficient engine removal.

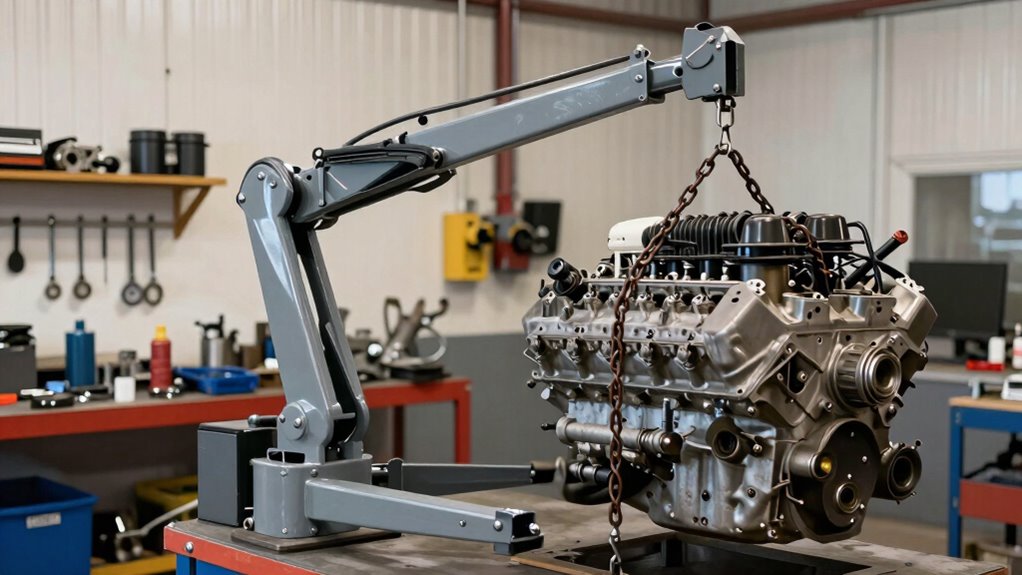

Common Engine Hoist Types

Engine hoists come in several types, each designed to handle different engine sizes and lifting needs. The most common are hydraulic engine hoists, which rely on hydraulic systems to provide smooth, controlled lifting. These hoists are known for their engine durability, often built with sturdy steel frames to withstand repeated use. Portable models are lightweight and easy to maneuver, making them ideal for small garages or occasional use. There are also shop cranes, which are larger and more robust, suitable for frequent heavy-duty lifting. Some hoists feature adjustable arms or foldable designs for added versatility. When selecting an engine hoist, it’s important to consider the capacity ratings to ensure it can handle your specific engine weight safely. Additionally, choosing a model with quality hydraulic systems and durable components helps ensure safety and longevity during your engine lifting tasks. Selecting the right hydraulic system can significantly impact the efficiency and safety of your engine lifting process. Proper maintenance of hydraulic components is essential to prevent failures and extend the lifespan of your hoist. Whichever type you choose, make certain it’s built with quality hydraulic systems and durable components to guarantee safety and longevity during your engine lifting tasks.

Typical Capacity Ranges

Engine hoists are available in a range of capacity options to suit different vehicle sizes and lifting demands. Most models adhere to common capacity standards, typically ranging from 2 to 5 tons. Smaller hoists, around 2 tons, are ideal for compact cars and light-duty tasks, while 3 to 4-ton hoists handle most passenger vehicles. Heavy-duty models, up to 5 tons, are suitable for larger trucks and heavier engines. Hydraulic power plays a vital role in lifting efficiency, providing smooth and controlled operation across capacity ranges. When selecting a hoist, always verify that it meets your vehicle’s weight and lift requirements, ensuring safety and performance. Knowing these typical capacity ranges helps you make an informed decision tailored to your specific engine removal needs. Understanding capacity standards is essential for selecting the right hoist and ensuring safe operation. Additionally, considering the material quality of the hoist can impact durability and safety during use. Proper maintenance and inspection of the hoist are crucial to sustain its performance and safety over time, and regularly checking its components can prevent unexpected failures.

Choosing the Right Size

Choosing the right size of engine hoist depends on understanding the different types available and their capacities. There are various models designed for specific engine compatibility, from compact units for small engines to heavy-duty hoists for larger, industrial engines. Typically, capacities range from 1 to 5 tons, so selecting one that matches your engine’s weight guarantees safety and efficiency. Make sure the hoist meets manufacturing standards, which guarantees quality, safety, and durability. Consider the height and reach needed for your projects as well, since different hoists offer varying booms and extension options. Properly assessing your project requirements ensures you select a suitable hoist that provides both safety and convenience. By understanding these factors, you can pick a hoist that fits your engine size and workload, avoiding under- or over-investing in equipment that won’t serve your needs effectively.

How to Match Your Engine to the Correct Hoist Capacity: A Step-by-Step Guide

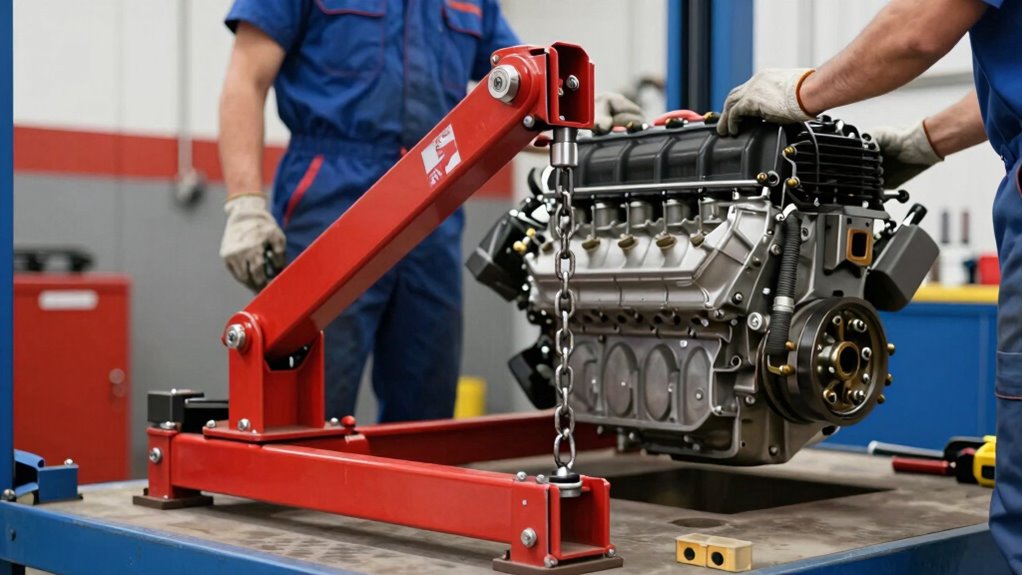

To match your engine to the right hoist, start by determining its weight accurately. Next, consider the engine’s dimensions to make certain it fits comfortably in the hoist’s reach. Additionally, select a hoist with a suitable capacity that exceeds your engine’s weight to provide a safe working margin. Finally, always add a safety margin to handle unexpected factors and ensure safe lifting.

Determine Engine Weight

Before selecting a hoist, you need to know the engine’s weight to make certain you choose a capacity that can handle it safely. To do this, check the engine’s specifications in your vehicle’s manual or on the engine itself. If you don’t have exact figures, weigh the engine using a scale or estimate based on similar models. Knowing the engine weight helps you determine the appropriate hoist capacity, ensuring it can lift the engine without strain or risk of failure. Properly matching the engine weight to the hoist capacity prevents accidents and ensures smooth, reliable lifting. Additionally, understanding equipment safety standards can help you keep related tools and references readily accessible during your maintenance or repair tasks. Being aware of lifting capacities also helps prevent overloading, which could cause equipment failure. Incorporating load capacity guidelines into your planning ensures safer and more efficient lifting procedures. Moreover, consulting manufacturer recommendations can provide specific capacity insights tailored to your equipment.

Consider Engine Dimensions

Understanding the engine’s dimensions is key to selecting a hoist that can handle it safely. To do this effectively, you need to measure accurately and consider mounting points. First, identify the engine’s length, width, and height to ensure the hoist can accommodate its size. Next, check the location and number of mounting points, as these influence the hoist’s attachment options. Finally, verify that the hoist’s hook height and reach match the engine’s dimensions for a secure lift. By focusing on engine dimensions and mounting points, you prevent selecting a hoist that’s too small or awkwardly shaped, ensuring safe handling during removal or installation. Accurate measurements are essential for a smooth, safe lifting process. Additionally, understanding the weight capacity of the hoist ensures it can handle the engine’s weight without risk of failure.

Add Safety Margin

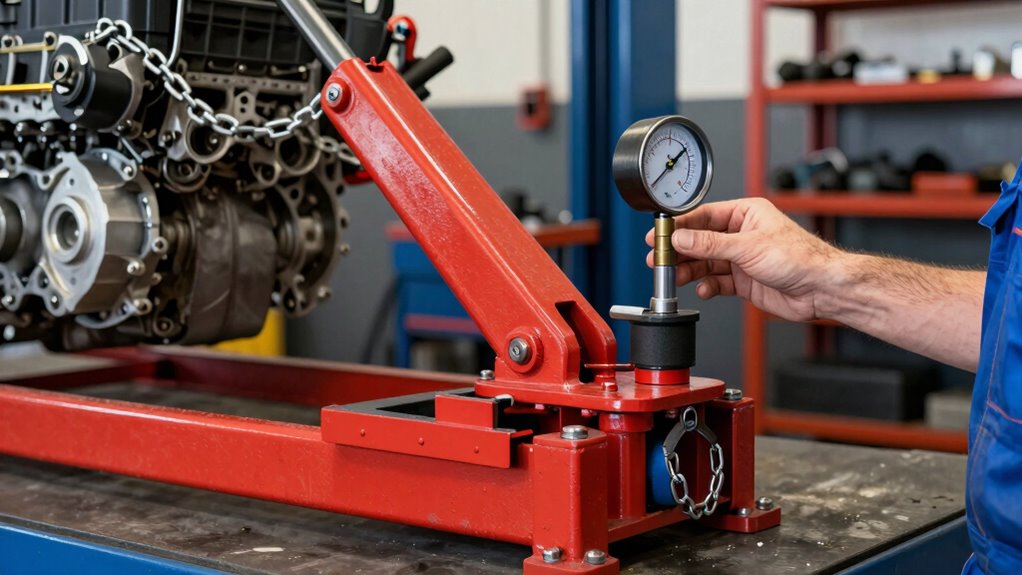

How can you guarantee your hoist safely handles your engine’s weight? The key is adding a safety margin during capacity planning. Never rely solely on the engine’s exact weight; instead, choose a hoist with a capacity at least 10-20% higher. This buffer accounts for variables like engine mounting hardware, slings, and potential shifting during lifting. Prioritizing engine hoist safety means avoiding overloading, which can lead to equipment failure or accidents. When selecting a hoist, always check the maximum capacity and compare it to your engine’s weight, then add your safety margin. This practice ensures you have enough capacity for safe, reliable lifting. Proper capacity planning is essential for safe, efficient engine removal and installation.

Common Mistakes When Choosing an Engine Hoist (And How to Avoid Them)

Choosing the wrong engine hoist can lead to safety hazards, costly repairs, or even damage to your engine. A common mistake is neglecting proper capacity estimation, which risks capacity misjudgment. To avoid this, consider these points:

- Overestimating your engine’s weight, leading to an underpowered hoist.

- Ignoring the maximum load capacity and exceeding it during lifting.

- Overlooking the hoist’s lifting height, which could cause stability issues.

These errors compromise engine hoist safety and can cause accidents. Always double-check your engine’s weight and choose a hoist with a safe margin of capacity. Proper planning prevents mishaps and ensures a smooth, safe lifting process. Avoiding capacity misjudgment is essential for safe, effective engine removal.

Safe Lifting Tips for Using Your Engine Hoist Properly

To guarantee safe and effective lifting with your engine hoist, always follow proper operating procedures and safety guidelines. Before each use, inspect your hoist for signs of wear, loose bolts, or damage—good hoist maintenance prevents accidents. Ensure the load is balanced and securely attached with appropriate chains or straps. Always lift slowly and steadily, avoiding sudden jerks that can destabilize the hoist or load. Keep clear of the area beneath the load, and never exceed the hoist’s weight capacity. Maintain a firm, stable footing and avoid lifting on uneven surfaces. Regularly check the hoist’s cables, pulleys, and hydraulic components for wear or leaks. Practicing lifting safety and proper hoist maintenance minimizes risks and guarantees safe, smooth operation every time.

When Should You Rent or Upgrade to a Larger Hoist?

Recognizing when your current hoist no longer meets your lifting needs is essential for safety and efficiency. If you notice issues with engine hoist durability, or if lifting techniques become more challenging, it’s time to contemplate renting or upgrading. Here are some signs:

- You frequently overload the hoist’s capacity, risking damage or failure.

- Your engine hoist shows signs of wear, such as bent arms or weakened chains.

- Your lifting tasks consistently require higher capacity than your current hoist can handle safely.

Upgrading ensures you maintain proper lifting techniques and safety standards. Renting a larger hoist temporarily can also be a smart choice if you’re unsure about future needs. Always prioritize equipment that matches your workload to prevent accidents and prolong tool lifespan.

Quick Checklist: Did You Choose the Right Capacity?

Ensuring you’ve picked the right hoist capacity is essential for safe and efficient lifting. Start by evaluating your engine’s weight and engine capacity, including the maximum load you’ll need to lift. Double-check that the hoist’s weight limit exceeds this total, allowing for a safety margin. Consider the type of engine and any additional accessories or attachments, as these can add weight. If you’re unsure, opt for a slightly higher capacity to enhance lifting safety. Remember, overloading a hoist can lead to accidents or equipment failure. Use this quick checklist to verify your choice: Does the hoist’s capacity surpass your engine weight? Is there enough margin for safety? Doing so ensures your lift is secure and your workspace remains safe.

Frequently Asked Questions

Can Engine Hoist Capacities Support Multiple Engines at Once?

Most engine hoists aren’t designed to support multiple engines at once, as this can exceed their engine compatibility and compromise hoist durability. Always check the weight capacity and specifications to verify it matches the combined weight of your engines. Using a hoist beyond its recommended capacity risks damage and safety hazards. For multiple engines, look for a heavy-duty hoist specifically rated for higher weights to maintain safety and durability.

How Does Engine Shape Affect Hoist Capacity Selection?

Engine shape critically impacts hoist capacity selection because irregular or heavy engine designs may require a higher capacity to guarantee safety and stability. You should consider capacity compatibility with the engine’s shape and weight distribution, as awkwardly shaped engines can exert uneven stress on the hoist. Always match the hoist’s capacity to your engine’s shape and size to prevent accidents and ensure smooth lifting operations.

Are There Weight Limits for Lifting Engines Over Long Distances?

Yes, there are weight limits for lifting engines over long distances. You need to take into account engine weight restrictions and long distance lifting considerations to ensure safety. Always check the hoist’s maximum capacity and verify it can handle the engine’s weight, especially over extended distances. Using the right equipment and adhering to weight restrictions prevents accidents and damage, making your lifting process safer and more efficient.

What Safety Features Should I Look for in a Hoist?

You should look for safety features like safety compliance certifications and reliable load-limiting devices in a hoist. These guarantee it meets safety standards and prevents overloading. Additionally, prioritize hoists that offer clear user training instructions and easy-to-use safety mechanisms. Proper safety features help reduce risks during lifts, keeping you safe and ensuring the engine’s secure transport over long distances.

How Does Ambient Temperature Impact Hoist Performance?

Ambient temperature acts like an invisible hand guiding your hoist’s performance. When it’s too cold, lubricants thicken, making movement stiff, while extreme heat can cause metal to expand, risking overstress. Temperature considerations are vital because they influence the durability and safety of your hoist. By understanding ambient effects, you ensure your equipment stays reliable, avoiding surprises and keeping your engine lifts smooth and safe, no matter the weather.

Conclusion

Choosing the right engine hoist isn’t just a detail—it’s your safety net, much like Icarus’ wings that must hold firm. By understanding your engine’s weight, selecting the proper capacity, and avoiding common pitfalls, you guarantee smooth lifts and peace of mind. Remember, a well-chosen hoist is your trusted partner, ready to lift your projects to new heights without falling into the trap of overconfidence. Lift wisely, and your work will soar.