If you’re looking for the best professional brake lathe machines for precise repairs in 2025, I’ve found top options that handle both disc and drum rotors up to 17 inches, with features like digital controls, micro-finishing, and quick changeovers. Heavy-duty models like the RL-8500XLT offer industrial capacity, while benchtop units are perfect for smaller spaces. Keep an eye on durability, ease of use, and compatibility with industry standards—stay tuned to discover which machines truly stand out.

Key Takeaways

- Top models offer high precision, micro-finishing, and digital controls for accurate brake rotor resurfacing.

- Heavy-duty construction with cast iron and steel ensures durability and vibration-free operation.

- Wide compatibility supports various vehicle types, including cars, trucks, and heavy-duty equipment.

- Features quick changeover, micro-adjustments, and industry-standard accessories for efficiency.

- Consider rotor size limits, operator training, and support services when selecting professional brake lathe machines.

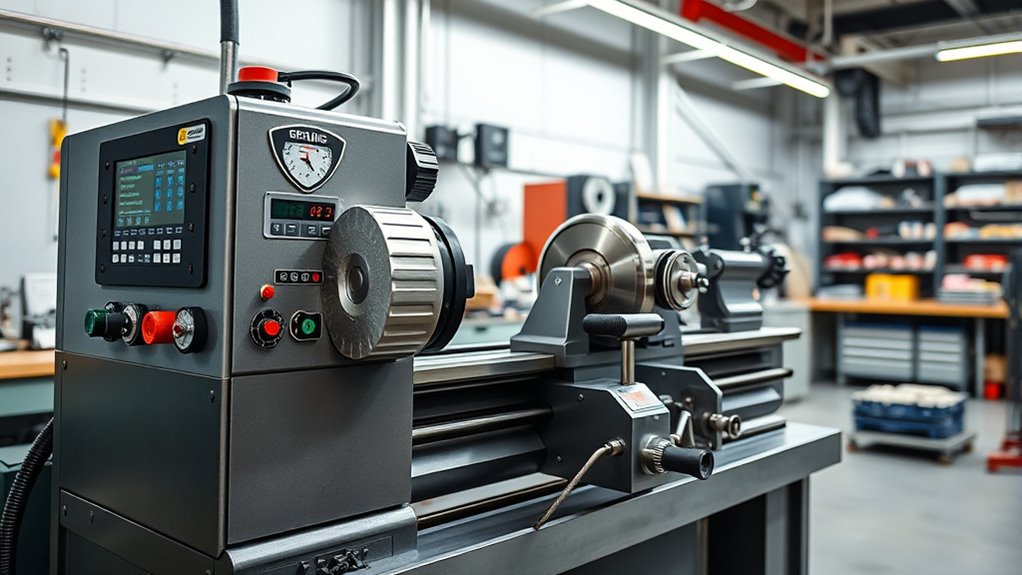

HPDMC Heavy-Duty Combination Disc/Drum Brake Lathe Machine

Motor: 110V/60HZ; Max Rotor Thickness: 2.5'' (64mm); Max Rotor Diameter: 17'' (432 MM)

As an affiliate, we earn on qualifying purchases.

Heavy-Duty Combination Disc/Drum Brake Lathe Machine

If you’re looking for a reliable brake lathe that can handle both disc and drum rotors with ease, the Heavy-Duty Combination Disc/Drum Brake Lathe Machine is a top choice. It features a powerful 110V/60Hz motor and can work on rotors up to 17 inches in diameter with a thickness of 2.5 inches. The spindle travel of nearly 7 inches allows for versatile servicing. Designed with simple, ergonomic controls, it minimizes operator effort. The package includes a sturdy bench, storage tray, and all necessary components, making it ideal for busy shops needing durable, efficient brake repair equipment.

Best For: professional auto repair shops and garages requiring durable, versatile equipment for servicing both disc and drum brake rotors efficiently.

Pros:

- Capable of handling rotors up to 17 inches in diameter and 2.5 inches thick, suitable for a wide range of vehicles.

- Simple ergonomic controls reduce operator fatigue and increase productivity.

- Comes with a sturdy bench and organized storage tray for convenient setup and tool management.

Cons:

- Limited to a maximum rotor diameter of 17 inches, which may not suit extremely large vehicles.

- Spindle speed range of 150-200 RPM might require adjustment for specific applications.

- Heavier weight (implied by the sturdy construction) could make mobility and repositioning more challenging.

Amazon Product B0D8KSGBYG

As an affiliate, we earn on qualifying purchases.

DMC-FFPS Heavy-Duty Brake Lathe with Bench & Tooling

The DMC-FFPS Heavy-Duty Brake Lathe with Bench & Tooling stands out as an ideal choice for professional shops seeking efficiency and precision in brake servicing. Its versatile design allows for quick progressions between rough cuts and micro-finishing in a single pass, saving time and ensuring a high-quality finish. The complete package includes a sturdy bench and easy-access tool tray, streamlining workflow. With precision cutter tools and a rapid drum-to-rotor changeover, it guarantees consistent results. Rugged construction, a hardened spindle, and user-friendly controls make it reliable and easy to operate, making it a valuable addition to any professional workshop.

Best For: professional auto repair shops and technicians seeking efficient, precise brake lathe operations for a variety of drum and disc brake servicing.

Pros:

- Versatile design allows for quick transition between rough cuts and micro-finishing in a single pass

- Includes a complete package with sturdy bench, tool tray, and comprehensive tooling for ease of use

- Rugged construction with a hardened, precision-ground spindle ensures long-lasting accuracy and durability

Cons:

- May require training or experience to operate the quick-change tool-head effectively

- Optional truck adapter kit is sold separately, adding to overall cost for full compatibility

- Heavier and larger setup might demand more space and handling in smaller workshops

VEVOR Metal Lathe, 8.3'' x 29.5'' Benchtop Metal Lathe 0-2500 RPM Continuously Variable Speed 750W Brushless Motor Metal Gears with LCD Display Metal Lathe Machine

Security Comes First: Our metal lathe machine has multiple security features in case of emergency, ensuring operator security....

As an affiliate, we earn on qualifying purchases.

Vevor Metal Lathe, 8.3 x 29.5 Benchtop Metal Lathe

Designed for detailed machining tasks, the Vevor Metal Lathe’s 8.3 x 29.5-inch size and powerful 750W brushless motor make it ideal for professionals who need precision and versatility. Its adjustable speed range from 50 to 2500 RPM, along with a dual-direction spindle, offers excellent control for various threading and cutting jobs. The LCD display ensures accurate speed adjustments, while the robust construction from HT200 cast iron guarantees durability. With safety features like overload protection and emergency stops, I feel confident working on complex parts. Overall, it’s a reliable choice for precision machining, though some users note minor alignment issues and limited support.

Best For: hobbyists and professionals seeking a durable, precise benchtop metal lathe for detailed machining and threading tasks.

Pros:

- High-quality HT200 cast iron construction ensures durability and long service life

- Variable speed control from 50 to 2500 RPM with digital display for precise adjustments

- Dual-direction spindle and support for multiple threading types enhance versatility

Cons:

- Some users report minor alignment issues with deviations up to .020 inches

- Difficulty in threading head support may affect complex machining tasks

- Limited technical support options, with no direct phone assistance available

KATRAX RL-8500 Combined Disc Drum Brake Lathe Benchtop Equipped with Standard Tooling, High Precision Industrial Grade Heavy Duty Commercial Maintenance Equipment

Heavy-duty and stable structure: Provides excellent weight support capacity, ensures stability during heavy-load operation, extends equipment life, and...

As an affiliate, we earn on qualifying purchases.

RL-8500 Disc Brake Lathe with Standard Tooling, Heavy Duty Maintenance Equipment

For heavy-duty workshops requiring reliable and durable equipment, the RL-8500 Disc Brake Lathe stands out with its robust, stable design that can handle high-intensity operations. It offers excellent weight support, ensuring stability during demanding tasks, which extends its lifespan and maintains consistent performance. The humanized control panel minimizes operator movement and fatigue, while the fast tool-free changeover saves up to 70% of setup time. Designed for industrial environments, it delivers precise speed and torque control for high-accuracy results. Its common adapters and noise-reducing technology create a quieter, smoother workspace, making it ideal for heavy-duty brake maintenance.

Best For: Heavy-duty workshops and industrial maintenance facilities requiring reliable, high-precision disc brake machining equipment.

Pros:

- Robust, heavy-duty stable design offers excellent support and durability for demanding tasks

- Fast, tool-free changeover reduces setup time by up to 70%, increasing productivity

- Quiet, vibration-reducing technology ensures cleaner cuts and a smoother workspace

Cons:

- May have a higher initial investment compared to lighter or less industrial-grade lathes

- Requires adequate space for stable operation in busy workshop environments

- Designed primarily for industrial use; may be overly complex for small-scale or occasional tasks

VEVOR 7×16 Metal Lathe Machine with 3-Jaw Chuck

If you’re seeking a compact yet powerful lathe machine capable of handling small-scale precision work, the VEVOR 7×16 Metal Lathe Machine with a 3-jaw chuck stands out. It features an 800W brushless motor that requires no belt drive or maintenance, and it offers a versatile speed range from 150 to 2500 RPM with digital controls. Built from durable cast iron, it includes useful accessories like a tool box and oil pan. Designed for precision tasks, it supports multiple thread types and metric or imperial measurements. While it has some common issues like alignment quirks, proper maintenance and adjustments make it an excellent choice for hobbyists and small shops.

Best For: hobbyists and small-shop users seeking a compact, low-maintenance lathe capable of precision small-scale metalworking tasks.

Pros:

- Features an 800W brushless motor eliminating belt drive maintenance

- Offers a wide speed range from 150 to 2500 RPM with digital controls for precise adjustments

- Built from durable cast iron with included accessories like a tool box and oil pan

Cons:

- Some users report alignment issues over longer workpieces, affecting accuracy

- Resonance and loose drive parts can impact stability during operation

- Common problems include faulty switches and material runout due to bed misalignment

Ranger RL-8500XLT Combination Brake Lathe

The Ranger RL-8500XLT Combination Brake Lathe stands out for its extended capacity spindle, capable of turning drums up to 10 inches deep, making it an excellent choice for shops that handle heavy-duty brake resurfacing. Its heavy-duty construction, including a 730-pound cast iron body and sturdy workbench, guarantees stability and minimizes vibrations, resulting in smooth finishes. The lathe features DC servo motor controls for both cross feed and spindle drive, providing precise adjustments and reliable operation. With unlimited feed rate adjustments and ample tool storage, it combines efficiency with convenience, making it a versatile and durable tool for demanding brake repair jobs.

Best For: automotive repair shops and professionals handling heavy-duty brake resurfacing who require high capacity, precision, and durability in their brake lathe.

Pros:

- Extended capacity spindle supports drums up to 10 inches deep, ideal for heavy-duty applications

- Heavy-duty cast iron construction minimizes vibrations for smooth, accurate finishes

- DC servo motor controls for precise, reliable operation and easy feed adjustments

Cons:

- Heavy weight of approximately 730 pounds may require multiple operators or equipment for setup

- Larger size (49 x 45 x 29 inches) could limit workspace flexibility in small garages

- Higher initial investment compared to smaller or less robust brake lathes

20 Pcs Carbide Lathe Inserts with Mounting Screws

Carbide lathe inserts with mounting screws stand out as essential accessories for professionals seeking quick, secure tool changes and consistent performance. I’ve found that the MorningRo 20-piece set offers a reliable, versatile solution for brake lathe and woodworking tasks. Made from solid carbide, these inserts deliver exceptional wear resistance and smooth cuts, even on tough materials like cast iron and dense woods. The negative rake design ensures precise, clean finishes with less tool pressure. The included mounting screws facilitate easy installation, while the organized red storage box keeps everything handy. Overall, this set enhances productivity and precision for both professionals and hobbyists alike.

Best For: DIY enthusiasts, professional mechanics, and woodworkers seeking durable, high-precision lathe inserts for brake servicing and detailed woodworking projects.

Pros:

- Made from solid carbide for exceptional wear resistance and long lifespan.

- Negative rake design provides smoother, cleaner cuts with less tool pressure.

- Includes mounting screws and organized storage box for easy setup and convenience.

Cons:

- Screws may wear faster and require periodic replacement.

- Less suitable for heavy-duty metalworking compared to specialized metal-cutting inserts.

- Compatibility with specific lathe models should be verified to ensure proper fit.

3 Piece Hubless Quick Chuck Adapter Set for 1 Arbor Brake Lathes

For professionals seeking quick and accurate rotor centering on 1 arbor brake lathes, the Piece Hubless Quick Chuck Adapter Set offers a highly practical solution. This 3-piece set is compatible with various brands like Ammco, Hunter, FMC, Accuturn, Ranger, and Atlas, fitting drums and rotors with centering holes from 2-1/8 to 3-3/4 inches. It includes a self-centering quick chuck, a standard backing plate, and a chuck key, with optional jaws expanding capacity to 5-3/4 inches for larger vehicles. Designed to reduce setup time and errors, it streamlines brake servicing while fitting multiple machines. It’s a reliable, versatile tool for professional brake repair.

Best For: professional mechanics and brake service shops seeking quick, precise rotor centering on 1 arbor brake lathes for efficient brake servicing.

Pros:

- Compatible with multiple popular brake lathe brands, ensuring broad usability

- Self-centering design reduces setup time and alignment errors

- Expands capacity to accommodate larger vehicles, including 1-ton trucks

Cons:

- May not fit newer Toyota rotors (2005+), causing fitment issues

- Some users find the tool overpriced relative to its single-function purpose

- Fitment and performance can vary depending on specific lathe models and rotor holes

VEVOR Metal Lathe Machine, 7 x 13.78, Precision Benchtop Power Lathe

If you need a precise and reliable benchtop lathe for small-scale professional or hobbyist work, the VEVOR Metal Lathe Machine stands out with its 7 x 13.78-inch working area and high-torque external poly-V-belt drive. This design triples output torque, making it capable of turning 45# steel bars with ease. It features a 20 mm spindle hole, four adjustable speeds up to 2200 RPM with a digital display, and a durable 500W brush motor with metal gears. The tailstock offers quick-lock and precise positioning, while safety features like overload protection and chuck cover disconnection guarantee operator safety. It’s an excellent choice for detailed, high-precision work.

Best For: hobbyists and small-scale professionals seeking a precise, reliable benchtop lathe for detailed metalworking projects.

Pros:

- High torque external poly-V-belt drive triples output torque, capable of turning tough materials like 45# steel.

- Multiple adjustable speeds up to 2200 RPM with digital display for accurate control.

- Safety features such as overload protection and chuck cover disconnection enhance operator safety.

Cons:

- Limited working area of 7 x 13.78 inches may restrict larger projects.

- Requires some technical knowledge for optimal operation and safety management.

- Not designed for heavy industrial use or large-scale manufacturing.

Vevor Metal Lathe, 8.26×28.3 inch, 750W Variable Speed Milling Machine

The Vevor Metal Lathe stands out as an excellent choice for professionals needing precise and reliable metalworking in tight spaces. Made from durable HT200 cast iron, it guarantees long-lasting performance and resistance to wear. Powered by a robust 750W brushless motor, it handles various tasks with ease. The spindle bore of 1.5/38 mm and the pre-installed 3-jaw chuck provide secure material clamping. With adjustable speeds between 50-2500 RPM, reverse and forward options, and safety features like an emergency stop, this milling machine offers versatile, high-precision operations suitable for small shop setups and complex projects alike.

Best For: professionals and hobbyists seeking a durable, precise metal lathe suitable for small shop or garage spaces.

Pros:

- Constructed from high-quality HT200 cast iron for durability and wear resistance

- Variable speed control from 50 to 2500 RPM allowing for versatile applications

- Comes with a pre-installed 3-jaw chuck and safety features like an emergency stop

Cons:

- Limited swing over bed at 8 inches may restrict larger workpieces

- The 750W motor, while powerful, may not handle extremely heavy-duty tasks as larger industrial lathes do

- Compact design might limit extensive customization or accessory options

Ranger RL-8500 Disc/Drum Brake Lathe with Bench and Tooling

The Ranger RL-8500 Disc/Drum Brake Lathe stands out for those seeking precise resurfacing with minimal vibration and chatter, thanks to its electric DC servo motor and innovative design. It effectively handles rotor, flywheel, and drum resurfacing, compatible with hubless drums and various rotor sizes. Its rugged build, large tool storage, and quick-change adapter system simplify setup and organization. The infinitely adjustable feed rates and advanced motor technology ensure smooth, accurate surfaces. Serpentine belts reduce noise and chatter, delivering a quieter, more efficient experience. Overall, it’s a reliable choice for professional brake service, combining precision, durability, and user-friendly features.

Best For: Professional automotive technicians and service shops seeking precise, vibration-free resurfacing of rotors, drums, and flywheels with user-friendly setup and organization features.

Pros:

- Rugged construction and durable materials ensure long-lasting performance.

- Infinitely adjustable feed rates for customized finishing quality.

- Quiet operation with serpentine belts and advanced motor technology reduces noise and vibration.

Cons:

- Heavy weight (678 pounds) may require strong handling during setup.

- Higher initial cost compared to basic lathe models.

- Large dimensions (45 x 38 x 29 inches) may require substantial workspace.

6920 Brake Lathe Silencer Band for Ventilated Rotor

For professionals seeking to minimize noise and chatter during brake lathe operations, the 6920 Brake Lathe Silencer Band for Ventilated Rotors offers an excellent solution. Designed for both small and large ventilated rotors, it’s made from durable rubber and metal load-bearing blocks, providing a secure grip. This adjustable strap reduces squeal and chatter, improving machining accuracy. Compatible with various brands like AMM CO, FMC/John Bean, Hunter, Kwikway, Van Norman, and RELS, it’s a versatile addition to your toolkit. Weighing just 5.9 ounces, it’s easy to handle, and the 30-day return policy guarantees peace of mind.

Best For: automotive professionals and technicians seeking to reduce noise and chatter during brake rotor machining on ventilated rotors across various brands and sizes.

Pros:

- Compatible with multiple brake lathe brands and models for versatile use

- Made from durable rubber and metal blocks to ensure a secure grip and long-lasting performance

- Effectively reduces squeal and chatter, improving machining precision and operator comfort

Cons:

- Some users notice differences in sound compared to older models, which may affect preferences

- Slightly heavier than similar accessories, which could impact handling during extended use

- Limited to ventilated rotors; not suitable for solid or non-ventilated rotor types

C-HORSE Negative-Rake Carbide Brake Lathe Bits (10-Pack)

C-HORSE Negative-Rake Carbide Brake Lathe Bits (10-Pack) stand out as an ideal choice for professionals seeking reliable, long-lasting replacement tips. Crafted from high-quality carbide, these bits deliver exceptional durability and resistance to wear, ensuring consistent, professional results. They’re compatible with popular models like Ammco 1000, 2002, 3000, and Hunter BL500/BL505, allowing for quick, hassle-free installation without special tools. Designed for precision, these inserts produce cleaner cuts and maintain accuracy during both light and heavy-duty tasks. Their straightforward design simplifies maintenance, saving time and reducing downtime, making them a dependable option for any professional brake lathe setup.

Best For: professionals and DIY enthusiasts seeking durable, precise, and easy-to-install replacement carbide brake lathe bits compatible with popular brake lathe models.

Pros:

- Made from high-quality carbide for exceptional durability and wear resistance

- Compatible with multiple popular brake lathe models for versatile use

- Easy to install without requiring specialized tools, reducing downtime

Cons:

- May be more expensive than generic or lower-quality alternatives

- Designed primarily for specific models, limiting universal compatibility

- Requires careful handling to prevent chipping or damage during installation

Factors to Consider When Choosing Professional Brake Lathe Machines

Choosing the right brake lathe machine depends on several key factors I always consider. You’ll want to think about vehicle compatibility, power, and capacity to match your repair needs. Additionally, ease of use, precision, and durability are essential for ensuring reliable, professional results.

Compatibility With Vehicles

Selecting a professional brake lathe that fits your vehicle lineup requires careful attention to compatibility. I look for machines that can handle the specific drum or rotor sizes I service, such as drums up to 10 inches deep or rotors with center holes from 2-1/8 to 6.25 inches. It’s essential to verify that the lathe works with both domestic and foreign vehicle models, including light trucks, passenger cars, and heavy-duty applications. I also check if it supports various hub and center hole configurations, like hubless designs or adapters for different mounting standards. Additionally, ensuring compatibility with different brake system types—ventilated, solid, or composite rotors—is vital for proper machining. Finally, I confirm the machine’s ability to accommodate common industry standards like Ammco, Hunter, FMC, or Ranger systems.

Power and Capacity

To guarantee a brake lathe machine can handle the demands of your shop, you need to pay close attention to its power and capacity. Confirm the machine has enough spindle horsepower and torque to work efficiently on the largest rotors and drums you service. Check that the maximum rotor diameter and thickness supported meet or exceed your biggest components. The spindle speed range, typically around 150-200 RPM, should suit both rough cuts and fine finishes. Also, verify the load capacity, especially if you plan to use heavy-duty arbors for trucks or larger vehicles, to avoid overloading. Finally, consider whether the machine can accommodate diverse rotor sizes, including deep or composite rotors, for versatile professional use.

Precision and Accuracy

The accuracy of a brake lathe hinges on its construction quality, especially regarding spindle and bed alignment, which directly affects the surface finish. A rigid build guarantees stability during machining, minimizing vibrations and errors. Precision models often include digital or dial indicators to verify rotor centering and alignment before starting. High-precision machines feature variable feed rates and fine adjustment controls, allowing for micro-finishing and reducing rotor runout. Maintaining consistent spindle speeds within tight tolerances, like ±1 RPM, ensures uniform cuts across various rotor sizes. Additionally, using high-quality, hardened cutting tools with positive rake cutter tips helps produce smooth surfaces with minimal material removal errors. Overall, these features are essential for achieving the high precision and accuracy required for professional brake repairs.

Ease of Use

When choosing a professional brake lathe, ease of use is crucial for maximizing efficiency and minimizing operator fatigue. Ergonomic controls positioned for minimal movement help reduce strain during long sessions. Quick-change systems, like tool-head or adapter swaps, allow for faster setup and turnaround times, boosting productivity. Intuitive control panels with clear labels and digital displays make it easy to adjust speeds and feed rates accurately, even for less experienced operators. Machines with straightforward manual options are perfect for beginners, reducing the chance of user error. Additionally, user-friendly safety features such as accessible emergency stops and protective covers enhance confidence and safety. Overall, a machine that’s simple to operate ensures smoother workflows and better results, making ease of use a key factor in choosing the right brake lathe.

Durability and Build

Durability and build quality are essential factors that determine a brake lathe’s long-term performance and reliability. I look for machines made from high-quality materials like cast iron or steel, which can withstand heavy use and resist wear. Reinforced spindle components and precision-ground parts are vital to maintaining accuracy and preventing misalignment during extended operation. A robust construction helps minimize vibrations and chatter, resulting in consistent surface finishes and fewer repairs. I also prioritize models with heavy-duty bases and supports, especially when working on large or heavy brake components. Additionally, a good build includes corrosion-resistant coatings or materials, ensuring the machine endures in demanding workshop environments. Overall, a well-built lathe offers longevity, stability, and dependable performance.

Versatility of Functions

A brake lathe’s ability to handle various repair tasks depends heavily on its versatility of functions. A versatile machine can work on both disc and drum brake components, broadening its application range. Adjustable feed rates and cutting speeds allow for different types of cuts, from rough to fine finishing, ensuring precision. Compatibility with various rotor and drum sizes means I can use the lathe on cars, trucks, or heavy-duty equipment without hassle. Multi-function models with quick-change tool heads and adapters help me switch operations rapidly, saving time. Advanced brake lathes equipped with digital controls and programmable settings let me customize machining parameters based on material and finish requirements. This adaptability ensures I can meet diverse repair needs efficiently and accurately.

Support and Maintenance

Selecting a professional brake lathe means ensuring it offers reliable support and straightforward maintenance. I look for machines that come with extensive technical support, including accessible customer service and troubleshooting resources, so I can resolve issues quickly. Clear guidelines on regular maintenance tasks like lubrication, part replacement, and calibration are essential, along with manufacturer support to keep the machine running at peak performance. I also verify the availability of replacement parts and tooling, such as cutters and adapters, to reduce downtime. Additionally, I consider the warranty coverage—its duration and what repairs it includes—to protect my investment. Ultimately, I prefer machines with clear maintenance schedules and instructional materials that make upkeep simple, helping extend the lifespan of my equipment and ensuring consistent, precise results.

Frequently Asked Questions

What Safety Features Are Essential in Professional Brake Lathe Machines?

Safety features are vital in professional brake lathe machines. I always look for machines with emergency stop buttons, which quickly shut down the equipment if needed. Guarding around moving parts is essential to prevent injuries, and adjustable clamps keep the rotor stable during operation. Good ventilation helps manage brake dust, reducing inhalation risks. Finally, clear safety instructions and proper training make certain I operate the lathe safely and effectively.

How Does Machine Weight Impact Portability and Workspace Requirements?

Think of a brake lathe’s weight as its muscle, directly affecting how easy it is to move and fit into your workspace. Heavier machines are like sturdy elephants—stable but tough to relocate—while lighter ones are like agile gazelles, easy to handle but potentially less stable. I find that balancing weight with workspace size helps me choose a machine that’s both practical and efficient for my repair needs.

Are There Environmentally Friendly or Energy-Efficient Brake Lathe Options?

Yes, there are environmentally friendly and energy-efficient brake lathe options available. I look for models with low power consumption and eco-friendly manufacturing materials. Some lathes feature energy-saving modes or are made from recyclable components, helping reduce environmental impact. Choosing a machine with these features not only benefits the planet but also lowers operational costs. I recommend researching brands committed to sustainability for the most eco-conscious choices.

What Maintenance Routines Ensure Long-Term Machine Precision?

Did you know regular maintenance can extend your brake lathe’s lifespan by up to 30%? To keep your machine precise, I recommend checking and cleaning the spindle and chuck weekly, lubricating moving parts as needed, and inspecting belts and electrical connections monthly. Always follow the manufacturer’s guidelines and keep a detailed maintenance log. This routine guarantees consistent accuracy and reliable performance over the long haul.

How Compatible Are These Lathes With Aftermarket or Custom Tooling?

These lathes are generally highly compatible with aftermarket and custom tooling, making them versatile for various repair needs. I always double-check the manufacturer’s specifications, but most modern machines support a wide range of tools thanks to standardized mounting systems. This flexibility allows me to customize setups for specific jobs, guaranteeing precise results every time. Just verify your tooling matches the machine’s specifications to avoid compatibility issues.

Conclusion

Choosing the right brake lathe is like finding the perfect compass for your journey—guiding you with precision and confidence. Each machine is a beacon, illuminating the path to flawless repairs and lasting performance. Remember, the right tool isn’t just equipment; it’s your trusted partner, turning complex tasks into a smooth voyage. With the right choice, you’re equipped to navigate every repair confidently, steering your work toward excellence.